NORMAL

Normal is the basic version of the De Nardi overhead doors. The door frame is made with an exclusive reinforced steel profile designed to house the rubber sealing strip. A practical system of counterweights is inserted into the galvanized steel side uprights for easy, effortless opening. Metal parts are galvanized and painted on request with RAL colors and with stove-enamelled polyester-powder finish for maximum weatherproofing. The door is covered in okoumè wood multilayer panels on the outside with grout lines in different compositions. The overhead door Normal is lined on the inside, between the metal omega-shape bars, with plywood panels. The overhead door Normal may be supplied with a pedestrian door, glazed area and, for an even easier opening, with an electric motor. Normal is supplied with a Yale - type lock with handle, an anti-fall system and anchoring rag bolts.

Sizes up to L 550 x H 280 cm

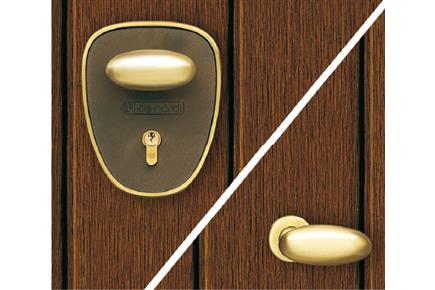

Handles

The coordinated, overhead and pedestrian door are six:

Satined brass with plate

Satined brass with plate

Satined steel brass with plate

Satined steel brass with plate

Natural satined brass

Natural satined brass

Satined steel brass

Satined steel brass

Bronze-finish satined aluminium

Bronze-finish satined aluminium

Natural satined aluminium

Natural satined aluminium

Pedestrian door

Version with 3 point locking system

Version with 3 point locking system

Top locking

Top locking

Central locking

Central locking

Bottom locking

Bottom locking

Aeration

Two models for the aeration: round outlets or rectangular louvred grilles in dark brown ABS.

Glazed fanlights

Fixed and openable

Automation

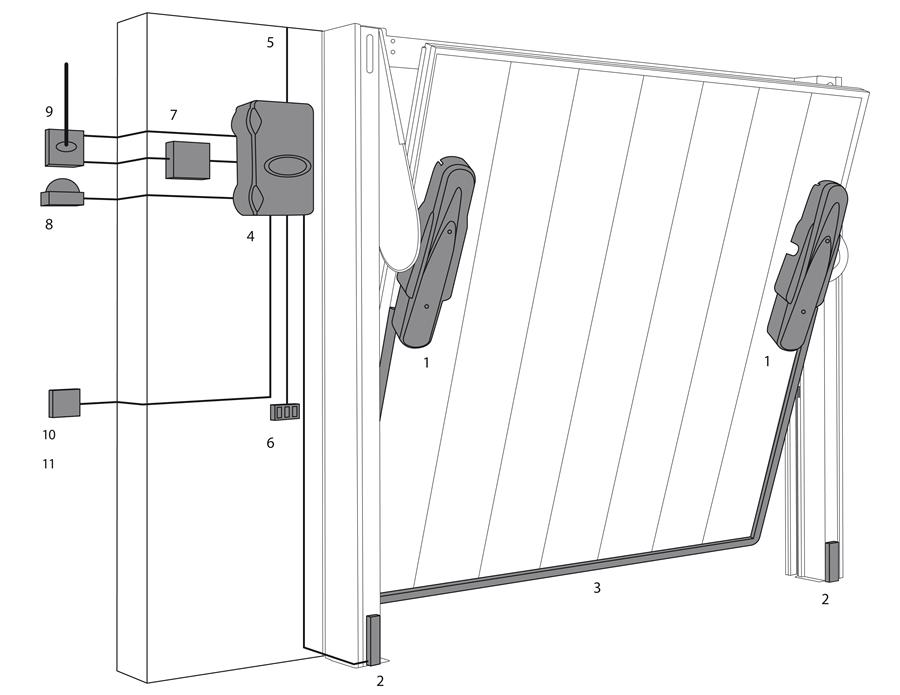

AUTOMATION ON BOARD 24V: DE NARDI (RESIDENTIAL USE)

The “GEARMOTORS DN 24” are installed exclusively on overhead doors De Nardi. Two leading companies that provide a service to the highest of quality and safety. The innovative automation device De Nardi is the thinking mind of the whole system: it manages the speeds to reduce the mechanical stress of the motors and gates; it segnals the archievement of the working cycles limit to require the maintenance; it also deals with the management of a long series of functions, including: lock and unlock buttons, opening by a photocell, reversal of the motor controlled by the anti-crushing rib, photocells, buffer batteries for emergency operation in the event of a power failure.

1 Motor block

2 Photocell

3 Mechanical rib

4 Automation device

5 Supply from breaker switch

6 Internal pushbutton

7 Radio receiver

8 Flashing light

9 Antenna

10 External key selector

11 Two-channel transmitter or four-channel transmitter

COMPONENTS

Electronic control unit with built-in antenna and radio receiver

Electronic control unit with built-in antenna and radio receiver

Engine carter

Engine carter

AUTOMATION ON BOARD 230V: DE NARDI (SHIPBUILDING USE)

Automation consists of one or two electromechanical locks with motor 230V A.C. and high resolution encoder, connocted to the overhead door by two telescopic arms and equipped with:

- limit switches for opening and closing,

- internal and/or external emergency release (commanded from the lock) for the handling in case of absence of the mains voltage.

The automation is supplied wired for the devices to the side described, with junction box to fix to the wall on the right side (internal view) and complete with power cable “schuco” type.

The electronic control unit has a detection system of the stress profile and self regulation of engine delivered to the stress profile and self regulation of engine delivered to the engine during the cycle of opening and closing in order to limit the impact forces in compliance as provided by law.

It’s also possible the automatic timed closing and the regulation of the engine power.

The mobile door is supplied with a bumper rubber to protection of the three sides.

AUTOMATION DEVICE ON BOARD

Automation device on board, with courtesy light (max 25W) and button of opening/closing, equipped with various outputs for connecting peripherals such as:

- key selector

- photocells

- flashing light 230V

- external courtesy light (maximum power 250W, no neon)

- base for two-channel receiver radio

- mechanical anticrushing rib to protection of the three sides

The automation is supplied wired for the devices to the side described, with junction box to fix to the wall on the right side (internal view) and complete with power cable “schuco” type. The electronic control unit has a detection system of the stress profile and self regulation of engine delivered to the stress profile and self regulation of engine delivered to the engine during the cycle of opening and closing in order to limit the impact forces in compliance as provided by law. It’s also possible the automatic timed closing and the regulation of the engine power. The mobile door is supplied with a bumper rubber to protection of the three sides.

Electronic control unit on board

Electronic control unit on board

Courtesy light

Courtesy light

Mechanical anticrushing rib

Mechanical anticrushing rib

Kit antintrusione